FDSP Quality Engineering Series|Pet Food Engineering

2024-03-28

About

Jiangsu Liangyou Zhengda Co., LTD. (referred to as FDSP share) was founded in 2003, located in Liyang High-tech Industrial Park, Jiangsu Province, on the border of Jiangsu, Zhejiang and Anhui. As a national high-tech enterprise, FDSP share does not forget the original intention, with the goal of "making first-class products and building high-quality projects", committed to the research, development and manufacturing of pet food technology and equipment, and customized high-quality pet food engineering system solutions for pet food manufacturers at home and abroad. Provide one-stop service from whole plant planning, process selection, equipment selection, installation and commissioning to operation training, maintenance and subsequent upgrade.

The company adheres to the enterprise spirit of "cooperation, creation, honesty and courage", adheres to the core value concept of "winning trust by sincerity and winning by quality", pursues the differentiated competition strategy of "creating a big difference in the same world", takes customer demand as the core, relies on high-tech products, and takes lifelong service as a commitment. Continue to create more and greater personalized value for customers at home and abroad, unswervingly seek "mutual benefit and win-win, common development" with customers.

Pet Food Engineering

Pet food refers to protein and fat as the main raw materials, including water, protein, crude fat, crude ash, crude fiber, nitrogen free extract, minerals, trace elements, amino acids, vitamins, etc., specially providing food for pets, small animals. It is a kind of high-end animal food between human food and traditional feed. It has the advantages of comprehensive nutrition, high digestion and absorption rate, scientific formulation, quality standard, easy feeding, and can prevent some diseases.

With the continuous improvement of people's living standards and the prosperity of the pet industry, consumers have put forward higher requirements for the production of pet food. FDSP share closely follow the market development trend, constantly strengthen the ability of independent innovation, upgrade and develop pet food technology, technology and equipment, in order to meet the diversified formula needs of customers, help customers improve product competitiveness, provide strong support for high-quality pet food production, and promote the sustainable economic development of the pet industry.

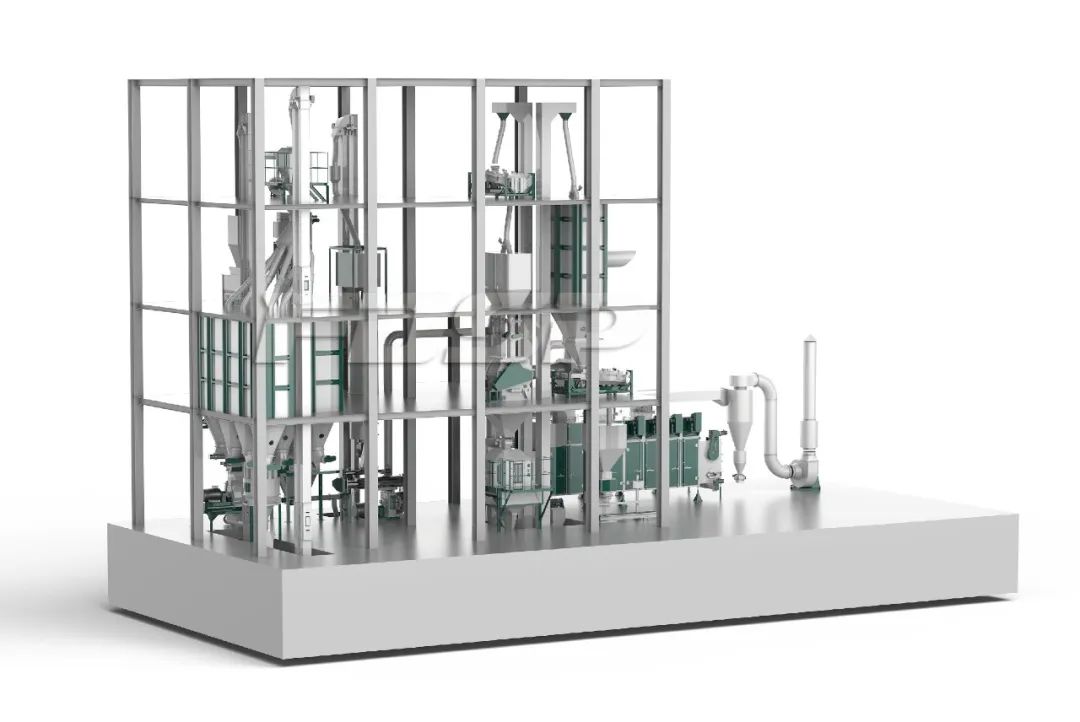

Section description

RM receiving and pre-cleaning section

The raw material feed port has a separate dust removal, good dust removal effect, and is equipped with a primary cleaning screen and permanent magnet cylinder to remove large impurities and iron impurities of raw materials.

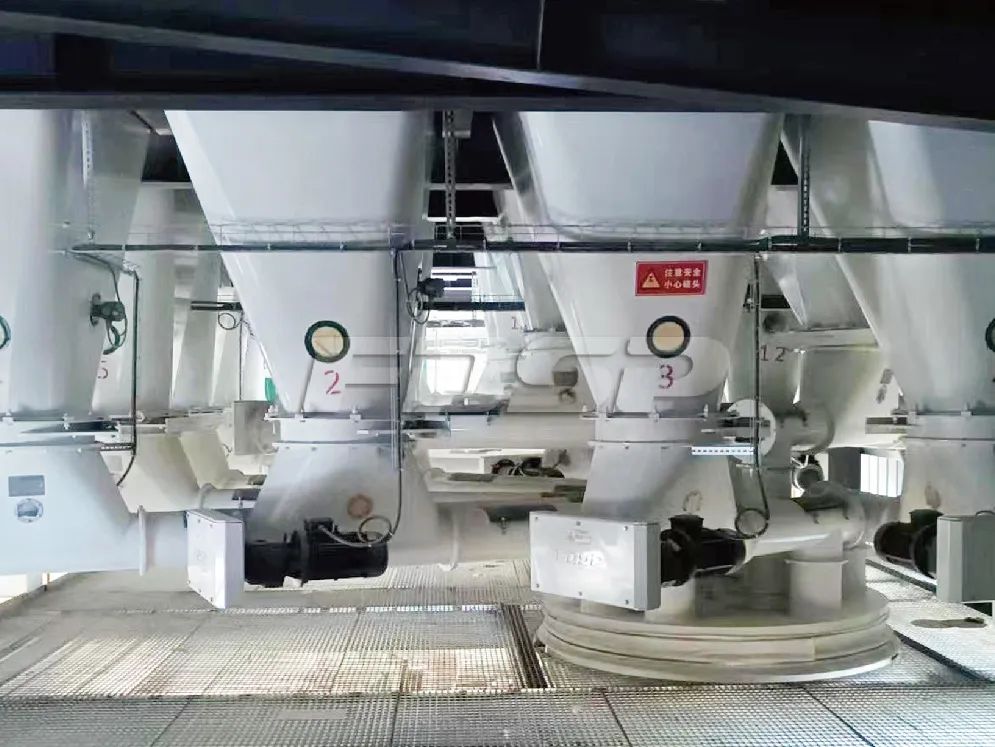

First batching section

This section is controlled by the dosing program independently developed by our company to achieve accurate fast and slow dosing, fast dosing speed and high precision.

First pre-mixing and grinding section

The ribbon mixer is used for pre-mixing to improve the uniformity of materials before crushing. Before the raw materials are put into the bins, the impurities are removed by the magnetic separation device to ensure the safe operation of the crushing function.

Micro grinding section

It adopts micro-hammer mill or pulverizer independently developed by FDSP share. It is discharged by air transport and configuration of cyclone, pulse filter.The fineness of grinding can be adjusted.

Second mixing section

Mixing with secondary ingredients, with a small material adding port, mixing uniformity CV≤5%.

Extruding section

Adopted FDSP share independently researched and developed pet food specially used single screw or twin screw extruder. Among them, the twin-screw extruder has a length-to-diameter ratio of up to 19.5:1, which makes its requirements for product formulation relatively loose and more adaptable, and its adaptability to high oil and high protein formulations is much better than that of ordinary equipment. The tempering system of the bulking machine can be equipped with dual-axis differential tempering device, which can make the material fully mixed with steam and water accurately, and the accurately designed differential structure can make the modulation temperature easily above 95℃, so that the material can be fully softened and pre-matured, which is of great help to improve the yield and product quality.

Drying section

PET food special dryer is used.It is imported brand PET fiber mesh belt,with high temperature shrinkable, high air permeability, and drying box and material contact parts are made of stainless steel,which is safe and hygienic. The special design of the hot air circulation system greatly improves the penetration and uniformity of the hot air and ensures the uniform moisture in the box. And can choose PC+ touch screen automatic intelligent control system, to achieve accurate temperature control.

Coating section

The spraying system can be customized according to the product requirements. The roller spray machine can be used for the conventional grease spraying. Frequency conversion continuous metering feed can achieve uniform grease spraying on the surface of particles. Mixed powder spraying equipment can also be customized, and the weight reduction silo can meet the proportion control of ingredients. Powder spraying slurry to solve the problem that the amount of oil added to the material in the early stage should not be too much and cannot meet the requirements of the amount of oil added, and the feed after spraying has a good appearance, strong palatability and strong nutrition.

Packing section

According to the different packaging of the final product, packaging scales of different measuring ranges can be selected, and auxiliary sealing equipment such as hot sealing machine, sealing machine, folding machine can also be selected.