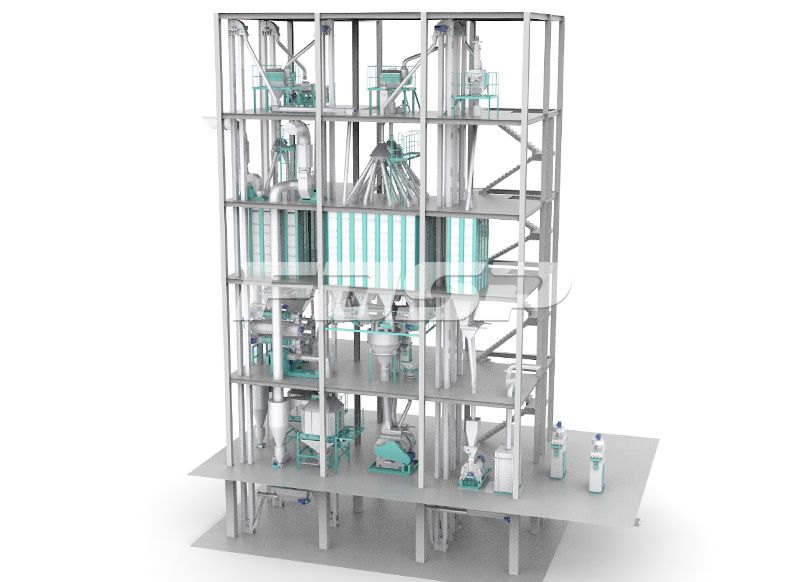

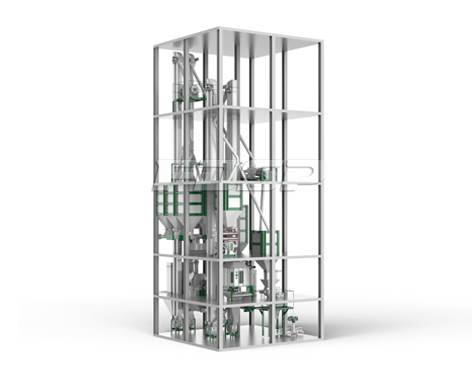

Single SZLH420(6-8tph) high grade piglet feed production line

The feeding of piglet has a lot of to do with its growing performance, so high grade pig feed is a kind of high-end feed including creep feed, piglet feed for earlier stage of pig. The high grade piglet feed should be with good palatability and piglet's preference, good digestion and absorption without diarrhea, high nutrition and production rate which ensure the pig could grow rapid and steady after weaning.

Jiangsu Liangyou Zhengda Co., Ltd is specialized in manufacturing feed machinery and engineering, we can offer customer complete machine solutions for livestock feed (pig and others), poultry feed (chicken, duck, goose and others), ruminant feed (cattle, sheep and others), normal aqua feed (four major Chinese carps), special aqua feed (shrimp, crab and others), extruding aqua feed (floating and sinking fish feed, shrimp and others), premix feed (including various additives), pet food (cat food, dog food and others), we can meet customers' kinds of needs.

Now we take the case of single SZLH420 (6-8tph) high grade piglet feed production line, make introduction based on process diagram and each process as follows:

Raw material:

maize, extruded maize, extruded soybean, extruded soybean meal, fish meal, salt, premix and etc.

Flow process introduction:

High grade piglet feed production line has following characteristics: fine grinded particles (the hole diameter of screen should be 1-2mm), high requirement for curing (the raw material will be cured first through expander), low conditioning temperature (adopt pelletize in low temperature), small diameter for finished pellet (the diameter around 2-3mm). The most raw material are all extruded (high curing for raw material), then grinded twice, mixed twice and pelletized in low temperature. The output for this SZLH420 high grade piglet feed production line is designed as 6-8t/h, with one grinding line, one batching and mixing line, one expanding line, one pelleting line and a bagging line. The total power will be 712KW, production area dimension is: 19x17.5x29m, matching 1T boiler. The whole line is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.

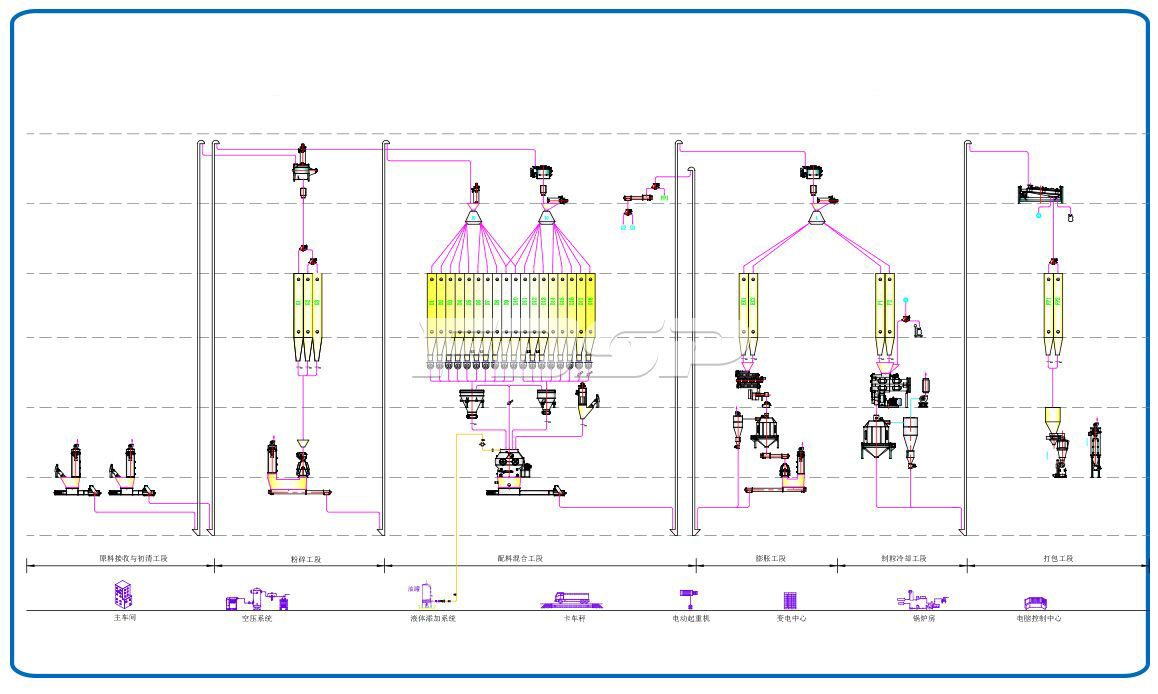

Technological process chart:

RM receiving and cleaning process--Grinding process--Batching and mixing process--Expanding process--Second grinding process--Second mixing process--Hypothermia pelleting process-Bagging process

Technological characteristics and introductions:

RM receiving and cleaning process:

In this process, the clean system for granule receiving and cleaning is separated from powder receiving and cleaning, dust collection are individual which is with the better effects.

Cleaner: granule precleaner SCY80, output 20-30t/h, powder cleaner SQLZ60×50×100, output 10-15t/h.

Grinding process:

1 set of hammer mill is adopt in this process, 3 grindings bins are equipped to cross exchange different raw material crushing; The impurities could be removed from raw material by magnetic separation equipment before grinding bins to ensure the safe running of hammer mill. As the high fineness requirement of high grade pig feed, the hammer mill in this process need to make twice grinding work so we use a large power hammer mill.

Grinding equipment: hammer mill SFSP668×1000, 160KW, output 8-10t/h (fine grinding)

Batching and mixing process:

In this process, we use 18pcs batching bins, two batching scale work at same time which is controlled by FDSP developed independently batching program, achieve accurate quick and slow feeding, quick batching and with high accuracy.

Weighing equipment: batching scale PCS10/PCS05, weighing accuracy: dynamic ≤3‰, static ≤1‰.

Mixing equipment: mixer SHSJ2, (18.5KW, 1000kg/batch), designed output 10-15 t/h/set, homogeneity CV ≤5%.

Expanding process:

The raw material will be expanded, heat sensitive materials will be added at the second batching process after expanded, then go to the pelletized in low temperature which could prevent the loss of heat sensitive element as possible. After cooling of expanded material, it will grinded twice then be raw material go to the batching bin trough conveyor.

expanding equipment: SPZS225, 200KW, designed output 8-10t/h(compound material)

Granulation process:

One set double conditioner pellet mill is used in this process. Two pellet bins are equipped for the pellet mill. After granulation, the pellets enter into the cooler (as there is no crumbling feed for high grade pig feed, so we do not use crumbler in this process), bucket elevator and then go to screening by rotary screener. The finished products go to the packing bins, others go back to the pellet mill other received by bags.

Granulation equipment: SZLH420, 110KW, output 6-8T/H(¢2.5mm piglet feed). Cooling equipment: SKLN6, output 10-15T/H.

Packing process:

There are 2 FP bins in this process. The pellet feed will be weighed and packed finally by packing scale.

Packing equipment: belt packing scale (both for mesh feed and pellet feed), weighing rage 20-50kg/bag, 6-8bags/min.

Auxiliary process:

Dust collection system can improve the work condition, the oil adding system is usually seen in the mixer adding system which can improve the feed palatability.

The process can be optimized according to different customer needs:

1. Single point dust collection mode is used in the plan which means pulse filter is equipped for every rotary distributor (mesh) and granule cleaner with good effect. Single point dust collection is kind of humanized design of our company, to provide a better working environment, but the cost increases, customers can consider whether it is needed in actual situation;

2. The quantity of bins can be adjusted to achieve the beast use ratio and effectively control the production cost based on factors such as customers' formula, characteristics of raw materials.