FDSP Premium Project Series|Rumination Feed Project

2023-12-01

About FDSP

Jiangsu Liangyou Zhengda Co.,Ltd. (FDSP) was founded in the year of 2003, which locates in Jiangsu Zhongguancun Science and Technology Industrial Park, Liyang city, boundary of Jiangsu, Zhejiang and Anhui provinces. As a national high-tech enterprise, Always keep the original intention, FDSP is committed to the ruminant feed processing technology research and development and provide high-standard grass pellet processing and high-performance total rations ruminant feed engineering system solutions for ruminant feed manufacturers and ruminant intelligent breeding enterprises. FDSP will make continuous independent innovation, upgrade technology, technology and equipment of ruminant feed to achieve sustainable development of ruminant industry green economy.

Ruminant feed engineering

Ruminant feed refers to the feed for cattle, sheep, rabbit, camel, deer and other ruminant animals, it is different from common single-stomach animal feed, it needs to contain necessary cellulose and microorganisms, so as to achieve efficient use of feed and promote animal growth.

FDSP focus on research, design, manufacturing and installation services for various types of ruminant feed engineering, customize complete set of ruminant feed production line for meat and sheep breeding and ruminant feed production enterprises, which integrates raw material receiving, automatic cleaning, rapid crushing, precise batching, uniform mixing, efficient pelletizing, cooling and sieving, automatic packaging and palletizing, to create “Safe feed, safe food” ruminant feed engineering.

Section description

raw material receiving section

According to the actual production needs, adopt scientific raw material reception technology, reduce energy consumption and production costs, reduce labor intensity, improve production efficiency.

Raw material cleaning section

achieve higher efficiency. The suitable screen hole size can be chosen based on material nature to get required result.

Grinding section

According to the grinded size required for ruminant feed, multi-chamber grinder is used here to improve grinding efficiency, meanwhile more than one grinding bins are equipped to meet the needs of different raw materials and greatly improve the production efficiency.

Batching section

It is controlled by the batching program independently developed by our company to realize accurate fast and slow feeding, fast batching and high precision. The batching bins are enlarged, the batching sequence control by program is also optimized.

Mixing section

According to grass material’s proportion and its light bulk density, the mixer with large volume, low speed and high uniformity is selected. The structure adopt is more humane and more easy to operate and maintain. Special design of the full-length open-door layout structure won the national patent.

Pelletizing section

According to the requirement of customers and ruminant feed process, we will select the Pellet mill, conditioner, retention system scientifically and save investment. It can be configured with multiple granulation bins to change feed type conveniently and realize high-efficiency granulation.

Cooling section

The feed temperature after cooling could be monitored in real time, optimized cooling air net system could ensure the desired cooling effect, high-efficient and reliable screening system could make the final products meet the needs of customers and the market.

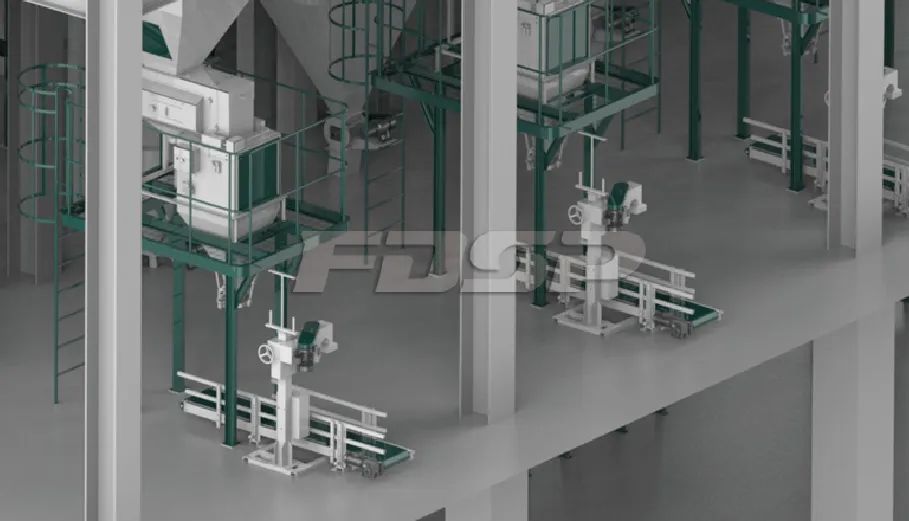

Package section

According to different finished products, accurate and efficient automatic packing scale with tonnage package or small package can be selected. What’s more mechanical palletizing system also can be equipped which greatly enhance the degree of automation, saving costs for customers.