Livestock And Poultry Feed Engineering

2023-09-21

About

Since its establishment in 2003, Jiangsu Liangyou Zhengda Co., Ltd. has been committed to the development and production of high-quality feed machinery and equipment to meet the needs of agriculture and animal husbandry.

As a leading enterprise in the field of livestock and poultry feed machinery and equipment, we have advanced production equipment and technical team. Our products include crusher, mixer, pellet mill, cooler, screener and other host equipment as well as elevating and conveying equipment, dust removal and iron cleaning equipment, extruding, drying and spraying equipment, intelligent control equipment, etc. These equipment has high efficiency, energy saving, durable and other characteristics, can meet the needs of different scale livestock and poultry farms and large agricultural and animal husbandry enterprise groups.

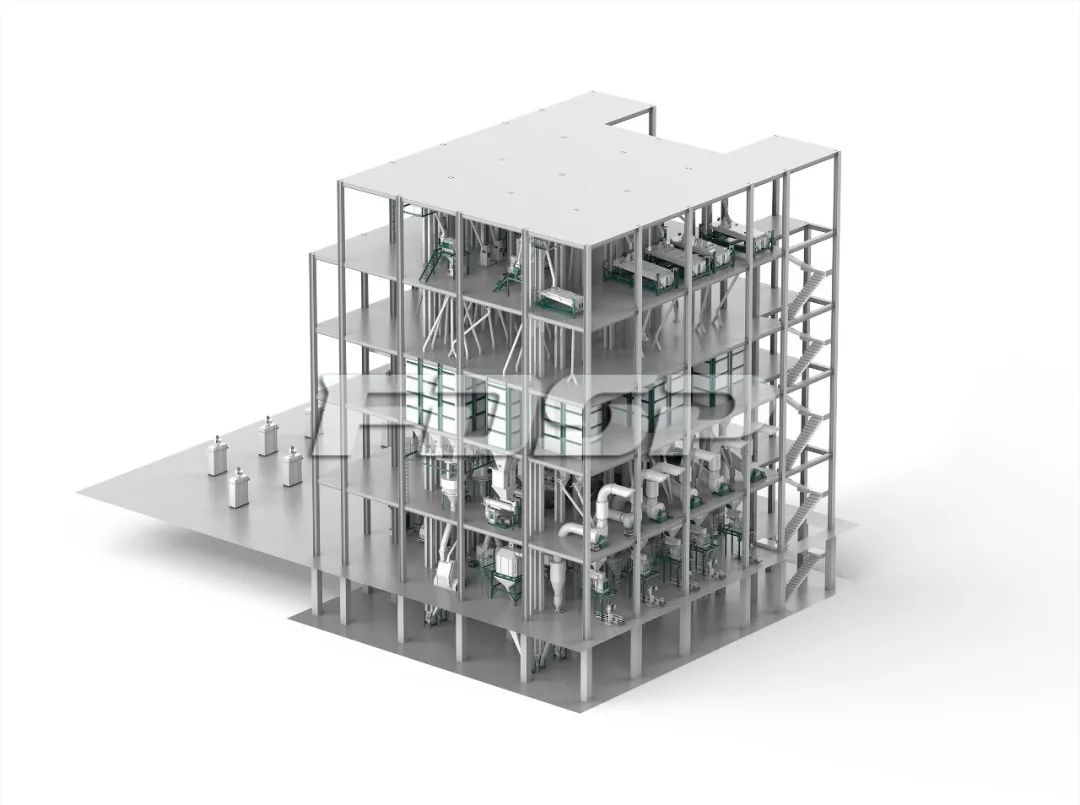

Livestock and poultry feed engineering

Liangyou Shares can tailor all kinds of livestock and poultry feed engineering services for domestic and foreign customers, including: chicken, duck and goose feed engineering, high-grade pig feed engineering, cattle and sheep ruminant feed engineering, bird and quail feed engineering, rabbit feed engineering, and deer feed engineering,etc. Our engineering team has rich experience in design and construction, as well as professional installation and commissioning knowledge, and can provide customers with comprehensive personalized solutions. Whether it is a new feed mill or the upgrading of an existing plant, we are able to provide customized design and engineering construction services.

Liangyou Shares has always been adhering to the "honesty, quality win" purpose, with excellent quality, superior technology, quality service to win the trust of customers. Over the years, we have established long-term and stable cooperative relations with many domestic and foreign collectivized and large-scale enterprises, and our products are sold at home and abroad.

Section description

RM receiving and cleaning section

In this section, the particle feeding cleaning and powder feeding cleaning are separated independently, and the dust removal effect is high. The suitable screen can be selected according to the properties of the material to achieve the required separation effect.

Grinding section:

The new cutter roller structure increases the cutting efficiency by about 10%, greatly reduces the use cost, and the new special material is used to greatly improve the service life. Chipping technology is the advanced level in the domestic.

Batching and mixing section:

The sprocket drive is changed to the intelligent transmission of the reducer box, and the new dual-shaft dual-coupling high-efficiency mixer with large volume, low speed and high uniformity is upgraded and customized, which can realize the start with material. The specially designed full-length open-door discharging structure has won the national patent.

Pelleting section:

The newly upgraded improved pellet mill, tempering and curing system and other equipment, combined with feed quality improvement requirements, efficient aseptic production, to meet the needs of a variety of high-grade livestock, poultry and aquatic feed.

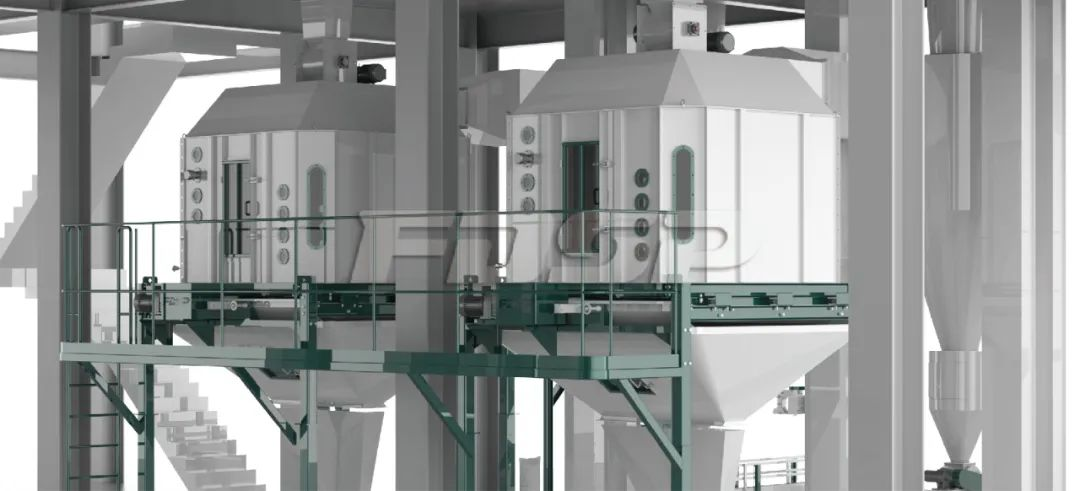

Cooling section

It can monitor the temperature of the cooled material in real time, optimize the designed cooling air network, and ensure that the predetermined cooling effect is achieved.

Screening division section:

According to the difference of the geometric size of raw materials and impurities, the screening surface is used for screening. The specially designed universal-joint hanging structure and flexible elastic support structure have stable operation and good screening effect. According to customer needs, one layer, two layer, three layer screen structure can be chosen, so that the finished particles to meet customer and market demand.

Automatic packing and palletizing section:

According to different finished materials, tons or small packaging automatic packaging scale is selected. The measurement is accurate, fast and efficient. Mechanical palletizing system can be allocated, which greatly improves the degree of automation, for customers to save costs.

Electronic control system:

High degree of automation, with computer full screen control or analog screen central control system. It can real-time monitor, so that you can know the operation of factory equipment at any time.